When Should Type D FIBCs Be Used?

When transporting or storing volatile or combustible materials in bulk bags, it is extremely important to choose static hazard controlling bags to prevent accidental discharges of static electricity. These discharges can cause the materials being transported to combust, leading to potentially fatal situations. A static hazard controlling bag such as the CROHMIQ® Type D FIBC will prevent static electricity from building up and potentially sparking an explosion.

Unlike other types of static hazard controlling packaging, Type D bags do not need to be grounded before they are filled. This provides a significant advantage in terms of safety because it eliminates the risk of human error. Type C FIBCs must be grounded before they are filled or discharged. In high-volume situations, this can lead to potentially hazardous oversights. Because they do not require grounding, CROHMIQ Type D FIBCs represent the highest level of safety for applications in which bulk bags are used for storing or transporting volatile and/or combustible materials.

FIBC Classification Types

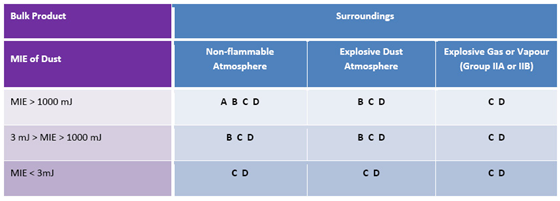

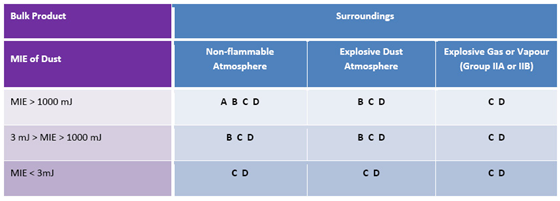

FIBC are classified according to one of four types. The types are defined by the construction of the bulk bag, the nature of their intended operation and associated performance requirements. The table below identifies which type of FIBC is appropriate depending on the sensitivity to ignition of the product being packaged and of the surrounding atmosphere. The sensitivity to ignition of the product being packaged, i.e., the bulk product, is defined by its minimum ignition energy (MIE). Surroundings are classified in increasing sensitivity to ignition by electrostatic discharges as non-flammable, explosive dust atmosphere, or explosive gas or vapor.

Type A FIBC are made from plain polypropylene or other non-conductive material. Static electricity is generated as products move over the inside surface of FIBCs when they are filled or emptied. As there is no static protection provided by Type A FIBCs, it is essential they are not used to store or transport combustible materials or used in flammable or combustible environments.

Read More…

Type B FIBCs are similar to Type A FIBCs in that they are made from plain polypropylene or other non-conductive material. And like Type A FIBCs, Type B FIBCs do not have any mechanism for dissipating or grounding static electricity. The difference is Type B FIBCs are made from materials that have a low breakdown voltage to prevent the occurrence of highly energetic and dangerous propagating brush discharges (PBD). Although Type B FIBCs can prevent PBD, they cannot be considered static hazard controlling FIBCs because they do not dissipate or Earth the electrostatic charge. So normal brush discharges can still occur, which can ignite flammable solvent vapors, gases, and dust.

Read More…

Type C FIBCs are conductive FIBCs. Originally, they were made from entirely conductive materials. Today, groundable Type C FIBCs are more commonly made from non-conductive polypropylene interwoven with conducting yarns, normally in a grid pattern. The interconnection of conductive yarns and the connection to ground or Earth are critical to the safe use of Type C FIBCs. As with any manual operation, ensuring interconnection and grounding of Type C FIBC is subject to human error.

Read More…

Type D FIBCs are made from static protective fabric designed to safely prevent the occurrence of incendiary sparks, brush discharges and propagating brush discharges, without the need for a connection from the bulk bag to ground or Earth. As CROHMIQ Type D FIBCs protect against incendiary sparks, brush discharges and propagating brush discharges, CROHMIQ can be used safely to package combustible products and for handling products in combustible and flammable environments.

Read More…